» PRODUKTION VON TIEFZIEHTEILEN, SCHLAUCHHÜLSEN, SCHLAUCHLEITUNGEN UND MEHR …

• PRODUKTION

Unser Maschinenpark umfasst 20 Transferpressen.

• WERKZEUGBAU

Unser Werkzeugbau steht für Flexibilität und Kreativität.

Gerne stehen wir Ihrem Projektteam zur Seite um das für Sie optimale Teil zu entwickeln.

Weiterhin steht unser hochqualifiziertes Personal stets für Werkzeugänderungen oder -reparaturen zur Verfügung. Interne Wartungspläne werden in regelmäßigen Abständen durchgeführt – je nach Häufigkeit der Produktionsabläufe bzw. der Hubzahl. Unsere Transferwerkzeuge bestehen aus einem Modulsystem von Einfachwerkzeugen, Stanzteilen aus Hartmetall, verschleißbeschichteten Stanzwerkzeugen, und all dem was benötigt wird um Ihr Teil herzustellen.

• QUALITÄT

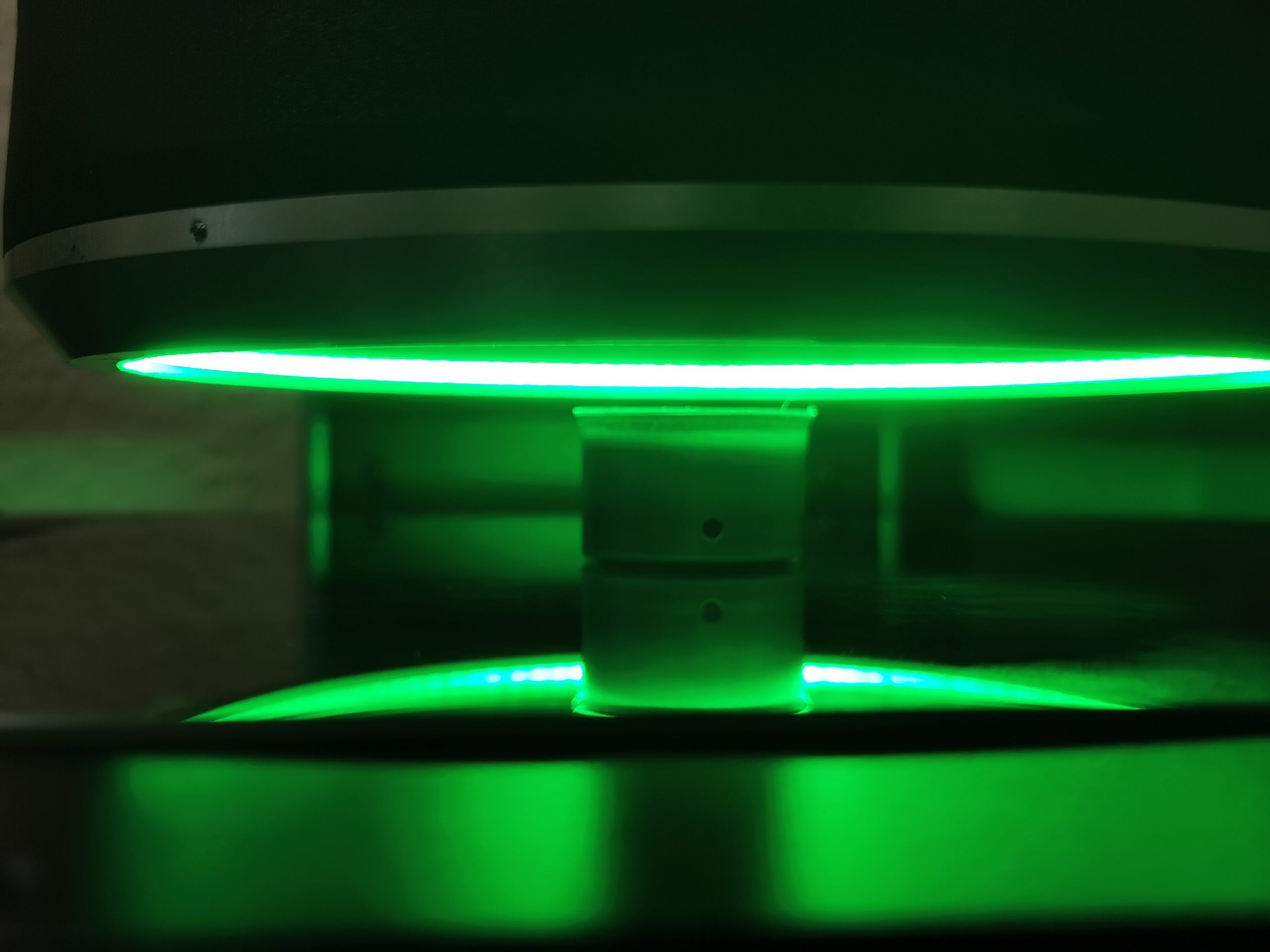

Die Serienfertigung von z.B. Tiefziehteilen unterliegt der ständigen Qualitätskontrolle nach DIN EN ISO 9001:2008.

Unser Ziel ist es Fehler vor der Entstehung zu erkennen und zu beseitigen. Jeder Mitarbeiter hat daher die Null-Fehler-Strategie als Grundlage seines täglichen Handelns.

Als langjähriger Partner der Automobilindustrie ist unsere Norm entsprechend an die ISO/ TS 16949 angelehnt. Produkt- und Materialrückverfolgbarkeit sind daher für uns selbstverständlich.

Um die Prozesse abzusichern werden produktspezifische Prüfpläne gemeinsam mit dem Kunden entwickelt. Die einhergehende statistische Prozesskontrolle ist somit ein Grundbaustein, um den hohen Qualitätsansprüchen unserer Kunden gerecht zu werden.